As industries such as frozen food delivery and preservation, medical and pharmaceutical shipping, and forensic evidence transportation increasingly rely on dry ice to conduct their business, the demand for proper storage solutions are on the rise. However, before you buy thousands of pounds of dry ice, there are many things to consider that are crucial to maintain dry ice’s quality, your safety and your budget; including whether you need to use dry ice at all.

What is Dry Ice?

Dry ice is the solid form of carbon dioxide (CO2) that is available in flakes, pellets or block form. Dry ice will sublimate directly into gas at -78.5°C (-109.3°F), a process that typically begins as soon as it is formed. Its extreme cold and non-liquid properties make it ideal for various applications. However, due to its economical, environmental and personal safety concerns, storage facilities must be properly equipped to safely store and transport dry ice.

Space and Layout

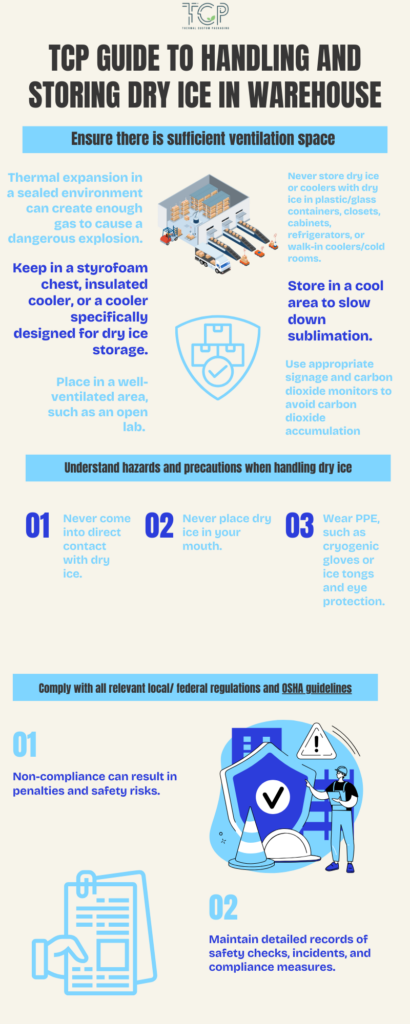

Evaluate the size and layout of your warehouse. Ensure there is sufficient space for storing dry ice and for staff to move safely around the storage area. Dry ice must be kept in a Styrofoam chest, insulated cooler, or a cooler specifically designed for dry ice storage, and placed in a well-ventilated area, such as an open lab. Never store coolers in closets, cabinets, refrigerators, or walk-in coolers/cold rooms.

Choose a location away from high-traffic areas to reduce the risk of accidents and disturbances. Consider the logistics of moving dry ice in and out of storage efficiently.

Proper ventilation is critical to prevent CO2 buildup, which can be dangerous or even deadly. Thermal expansion of dry ice (one pound produces about 250 liters of gaseous carbon dioxide) can create enough gas in a sealed container to cause an explosion. Therefore, dry ice should never be stored in tightly sealed devices like ultra-low freezers or plastic/glass containers.

Storage areas should have continuous mechanical ventilation or natural ventilation that provides adequate air exchange to maintain a safe environment.

Storage Equipment and Materials

Invest in high-quality insulated containers specifically designed for dry ice. These containers minimize sublimation, helping to preserve the dry ice longer. Even in a storage cooler, dry ice sublimates at a rate of five to ten pounds every 24 hours (blocks last longer). It is wise to purchase dry ice as close to the needed time as possible.

While dry ice will move in and out of your warehouse relatively quickly due to its short shelf life, it is still necessary to use sturdy, non-reactive materials for shelving and racks. They must support the weight and size of the insulated containers safely.

To try to slow down the sublimation process by storing dry ice at -78.5°C (-109.3°F) or colder. Implement reliable temperature monitoring devices to maintain optimal storage conditions and alert you to any deviations that could compromise the dry ice.

Safety Protocols

Dry ice is classified by the International Air Transport Association (IATA) and the FAA as a dangerous good and accordingly requires Dangerous Goods documentation, special handling, and ventilation.

Establish strict handling procedures that include using personal protective equipment (PPE), such as cryogenic gloves specifically designed for temperatures below -80°C or ice tongs, appropriate eye protection, and clothing to prevent frostbite.

Staff education should include training on the unique hazards of handling dry ice and the safety measures required to handle it. In addition to training, proper signage should be posted around the warehouse to remind all staff to take precautionary measures. Install CO2 alarms and develop clear emergency evacuation plans. Ensure staff are trained in first aid procedures for frostbite and CO2 exposure.

Additional guidelines and precautions for safe handling and storage of dry ice can be found in the Compressed Gas Association publication on Dry Ice.

Regulatory Compliance

Comply with all relevant local and federal regulations, including OSHA guidelines, to ensure safe handling and storage of dry ice. Non-compliance can result in penalties and safety risks.

Maintain detailed records of safety checks, incidents, and compliance measures. Regular audits help ensure ongoing adherence to regulations.

Inventory Management

Use inventory management software to track dry ice consumption, preventing shortages or excesses that could lead to waste or inefficiency, including a First In, First Out (FIFO) system to minimize waste, ensuring that older stock is used first.

Cost Management

Since dry ice begins sublimating as soon as it is created and can only be used once, suppliers will need to continue to replenish the stock, which can become costly. Estimate both initial setup costs and ongoing expenses. Aim to balance cost with efficiency and safety to maintain an effective storage system. Reduce energy consumption by investing in high-quality insulation and energy-efficient storage equipment, lowering long-term operational costs.

In addition to the costs associated with preparing for and purchasing dry ice, organizations should also budget for additional fees when shipping. Because of the risks associated with dry ice, companies will usually be charged a hazmat fee to cover the training and risk taken when shipping with this material. On average, hazmat fees range from $37.00 from UPS to about $180 from DHL.

Consider Alternatives

Dry ice isn’t the only option when it comes to the cold chain. Phase Change Materials (PCMs) are a cost-effective, green solution that is now enabling companies across multiple industries to ship temperature-sensitive materials without the headaches, risks and costs that come with storing and shipping dry ice. The differences between PCMs and dry ice ultimately depends on the specific requirements of your shipment, your budget, and your environmental considerations.

Consult the Experts

Take the time to evaluate your current dry ice storage practices and make necessary improvements to ensure safety and efficiency. Before you head down any path, consult with industry professionals for tailored insights and best practices to optimize your dry ice storage setup.

By considering these factors, you can ensure that your dry ice storage setup is both safe and efficient, protecting your investment and the well-being of your staff.