In the frozen food shipping industry, it’s essential to ensure products arrive fresh, safe, and of the highest quality. Our team of skilled professionals is at the forefront of revolutionizing cold chain logistics, combining expertise with cutting-edge technologies to tackle the unique challenges of frozen food transportation. From optimizing packaging solutions to developing eco-friendly processes, we’re committed to delivering innovative approaches that not only meet industry standards but set new benchmarks.

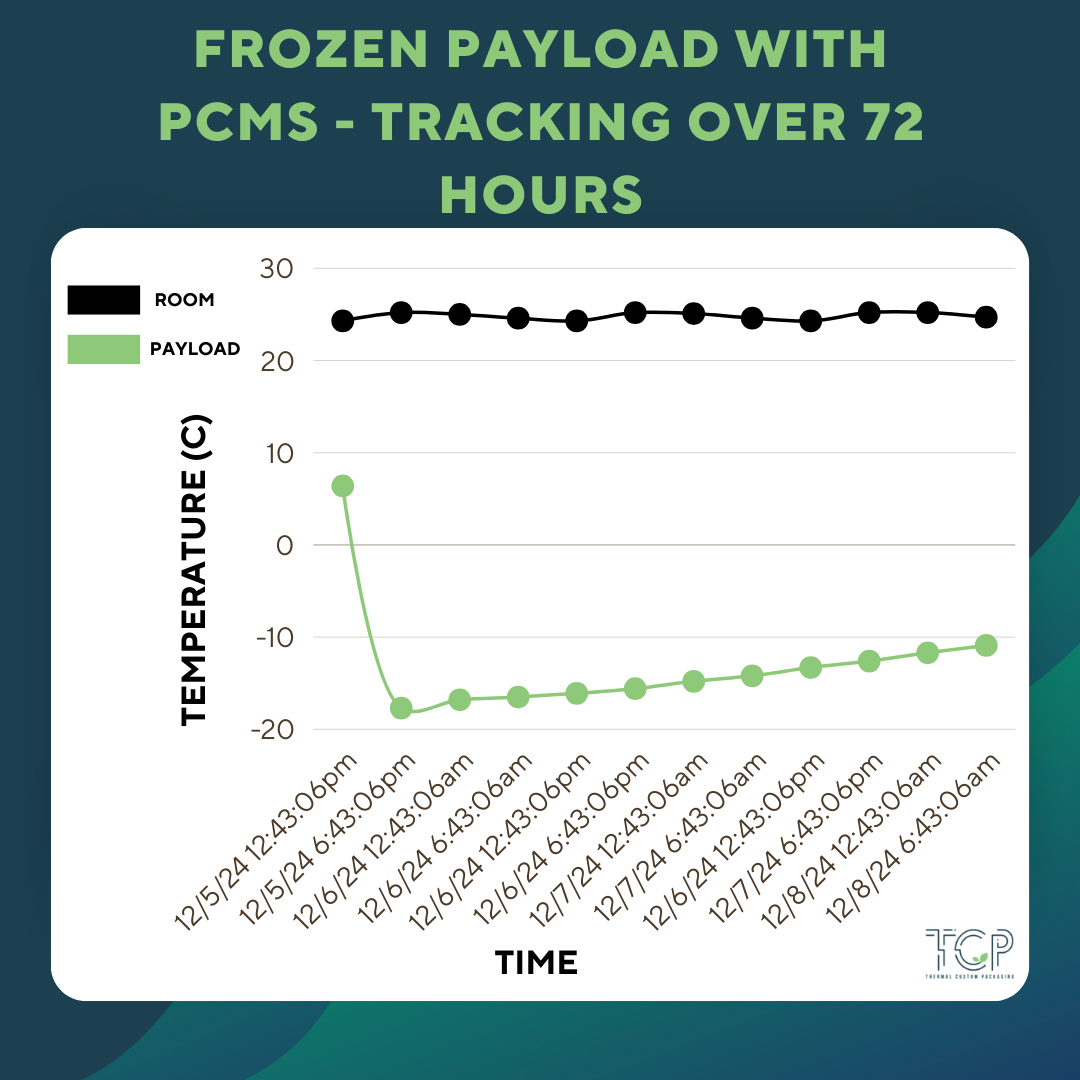

Thermal Custom Packaging can keep frozen payloads at their desired temperatures for over 72 hours. But, how is this possible? At TCP we are utilizing the power of VIP shipping panels combined with our Phase Change Materials.

Phase Change Materials or PCMs can store and release large amounts of energy allowing them to maintain a consistent temperature within a specific range for a long period of time. Depending on the environment and insulation, as well as the temperature of the payload, a PCM could maintain a consistent refrigerated, frozen, or ultra-cold temperature for multiple days. Because of its ability to be both customized by temperature and by size/weight, PCMs have a wide range of applications. The PCM plastic shells are made of HDHP plastic making them recyclable and the solution inside the hard plastic outer shell is non-toxic and environmentally friendly.

VIP panels, or Vacuum Insulated Panels, are advanced thermal insulation materials often used in temperature-sensitive shipping applications, such as for frozen food, pharmaceuticals, and other perishable goods. They are designed to provide superior insulation performance compared to traditional materials like foam or polystyrene. VIP panels consist of a core material (usually a porous substance like silica) encased in an airtight, multilayer barrier film. They use the vacuum effect to drastically reduce heat transference, making it ideal for frozen items.

Using these two products together allows for TCP to contain a stable frozen temperature unlike dry ice or traditional ice packs, both of which immediately start to lose effectiveness the minute they are taken out of their controlled temperature environments. Dry ice is also considered dangerous, which you can learn more about here.

See below: a graph of our timed temperature tests on frozen payloads over 72 hours.